This modification can be made without removing the main shaft from the helicopter (as a matter of fact, it is better to leave it installed to get the proper length of the main shaft when trimming).

Start by removing the main gear from the main shaft. Next using a 7/64" drill bit, carefully drill through the center of the main gear. Continue to enlarge the hole in 1/64" increments up to 7/32". Take care to ensure that the hole remains in the center of the gear. If is starts to get off-center, shave a bit off the 'thick' side with a #11 X-acto blade. Once the hole is 7/32" use the tapered reamer to enlarge the hole to a point where the one-way bearing (OWB) fits snugly in the hole. Place the bearing/gear assembly on top of the washer (to ensure proper clearance) and press down until the bearing is flush against the work surface and the main gear is flush against the washer. The side of the bearing with the washer thickness will be the top side so ensure that the OWB is properly oriented. Apply a thin bead of CA around the washer on both sides of the gear. Once the CA has cured, secure the gear/bearing assembly to the main shaft with a very small self-tapping screw that will thread into the main shaft without splitting the shaft.

1 Comment

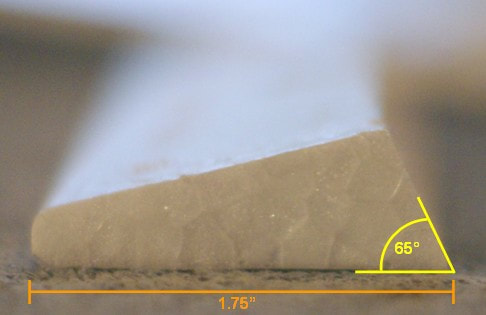

aileronsI purchased this kit since it is a trainer aircraft with optional floats so I can have something fun to fly off the water. The only thing that I didn't like is that it has no ailerons so I modified the wing to have ailerons. Each aileron is 9 inches long by 1-3/4 inches wide. I used a 65° cut on the leading edge of the ailerons to provide the clearance required for the 'up' movement. The parts I used are as follows: - Great Planes Small Nylon Control Horns (GPMQ3900) - DU-BRO Electric Flyer Hinge Tape (916) - Mini E/Z Connector (845) - Expert Electronics 6" Servo Y Harness (EXRA315) - 2 ea. Hobbico 12" Servo Extension (HCAM2100) - GWS Pico Servos WheelsI went with the DU-BRO 2-1/2" Super Lite Wheels (250SL) to aid in take-offs and landings off the grass. The wheels are held on with 4-40 Lock Nuts (GPMQ3344). wing strutsreapirsWhen it becomes necessary to make repairs to the foam parts of the aircraft, I have found a great product for making repairs. Woodland Scenics Foam Putty 16 oz. (ST1447) My first repair was to a scuffed wingtip where approximately 1/4" of material was ripped off the wing tip. This product is very easy to work with and is quite easy to sculpt, carve, and sand. new paintAfter a couple years I decided to give this bird a new proper color for a Cub.

This modification uses an electroluminescent panel behind the LCD to provide the backlight. This is preferred to an LED lighting scenario due to the uniform lighting from behind as shown in the picture. I have created technical instructions which provide full color photographs to guide you through the whole process, as well as a list of parts and where to get them. Please contact me here if you would like to order a copy of the instructions for $5.00 or if you have additional questions. FAQs

Q: What format does the technical document come in? A: The document is delivered in an Adobe PDF format. Q: What is included in the price? A: The complete technical instructions to accomplish the modification, a parts list, and required tools list. Q: How much current does this modification draw? A: My configuration shown above was measured at 38 mAh. Q: How long will this modification take? A: This modification should take an average modeler about 2 hours to complete. Q: Do I need any special tools? A: Anybody that has been into modeling for any time at all should have all the tools necessary to complete the job. A soldering iron will be required. Q: Can I turn the backlight on and off? A: The modification that I completed does not include a switch , but I did include a schematic and switch part numbers if a switch is desired. Q: Will this modification void my warranty? A: I have not personally confirmed this with Spektrum, but I would expect that it does void your warranty. Q: How much will the parts cost? A: The parts for my modification cost $38.00 including shipping. Q: Can these instructions be used for other models of transmitters? A: Although I have not modified another type of transmitter, you should be able to modify any LCD display that is accessible from the back side.

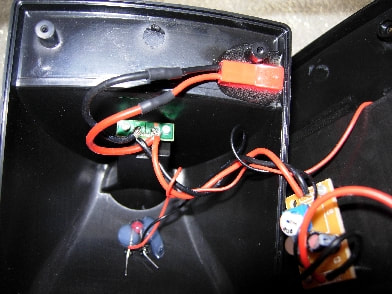

This charger, like it's predecessor, charges at a rate that, in my opinion is too high for the LiPo batteries (0.3A stated, 0.25A measured). The nice thing about the Celectra is that the charge rates can be adjusted between 0.1A and 0.3A for each port by adjusting the pot switches inside the unit (see photo). The inside of the unit can be accessed by removing the 8 small screws from the bottom of the unit (6 inside the battery compartment, and 2 under the rubber feet on the bottom like it's predecessor).

The connectors can be purchased separately, or you can salvage them from other places (i.e. the female end can be salvaged from an old single port charger and the male end can be salvaged from a dead battery). Once the adapters have been made, plug the male end into one of the charger ports, plug the battery into the female adapter, choose the current setting on your meter and adjust the pot to the desired current.

So far, the only thing that I have broken is the landing gear. What I have found is that glue does not stick to this plastic very well so I repaired it by wrapping the broken area with cotton thread and soaking it in CA then adding accelerator. This seems to be making a pretty good bond for now.

1S 3.7V LiPo Charger, 0.3A (this charger came with my mCX) The only real downside that I can find to the Blade mCX is the included charger. It is powered by four AA batteries which are used to charge the 110mAh flight battery. I have made the following modifications to allow the charger to be used as an adapter in conjunction with another LiPo capable charger.

CAUTION

When using the charger as an adapter with another charger, remove the AA batteries first. I have not tested to see if this causes a problem or not, so it is just a precaution until verified. I saw a tool like this at my LHS, but as usual, it was for the larger helis so I had to adapt for the smaller helis that I fly.

Once again, there are not any tools for the micro size helis, so I adapted the smallest pitch gauge I could find to accommodate the main blades of my Gaui Hurricane 200. I had some sheet styrene on hand so I layered multiple pieces together with plastic model cement and cut to fit the leading edge of the tool and viola! It now accommodates my Gaui main blades.

I have been toying around with a mount option for the DD setup and have come up with a very inexpensive solution. Two pieces of styrene tube from a local hobby shop. One great feature that I didn't plan on is that the mount does not need to be glued on to the tail boom. It fits snugly without the use of CA, so it can be removed in the event that you need to replace your tail boom.

The larger tube is 1/2" O.D. and has an I.D. just slightly smaller than the Pro/GWS motor O.D. By cutting the tube longitudinally, the expansion of the tube allows the motor to fit snugly without the use of straps, screws or glue. The smaller 1/4" O.D. tube is trimmed to accommodate the larger 1/2" tube and is cemented together with plastic cement. To further reinforce the joint, I have added a fillet of medium CA and sprayed with accelerator for further strength. The tubing I purchased was white and I have painted it black. The weight (with paint) is approximately 1g. I am using a GWS 3.0 x 2.0 propeller which has been painted black. |

Dan BlanchardThis is my collection of tips, tricks, and projects that I have made over the years while enjoying my various hobbies. Categories

All

Archives

July 2020

|

Site powered by Weebly. Managed by iPage

RSS Feed

RSS Feed